March 22, 2024

COLUMBUS, Ohio – Researchers have developed a more durable way to repair the dural membrane (dura) that lines the brain and spinal cord. The strong and highly adhesive hydrogel called Dural Tough Adhesive (DTA) solves key problems that may happen when repairing the dural membrane lining after trauma or surgery.

The dural membrane is the outermost of three meningeal layers that line the central nervous system (CNS), which includes the brain and spinal cord. Together, the meninges function as a shock absorber to protect the CNS against trauma, circulate nutrients and remove waste.

The dura also contains cerebrospinal fluid that surrounds all CNS tissues. Injury, trauma or surgery may cause the fluid to leak, which can threaten patients’ lives, neurological functions and recovery.

The dura also contains cerebrospinal fluid that surrounds all CNS tissues. Injury, trauma or surgery may cause the fluid to leak, which can threaten patients’ lives, neurological functions and recovery. “As neurosurgeons, we routinely open the dura to access the brain or spinal cord, but achieving a watertight seal of the dura after these procedures can sometimes be challenging,” said Kyle Wu, MD, a neurosurgeon and assistant professor at The Ohio State University Wexner Medical Center, College of Medicine and James Cancer Hospital.

Wu is co-first and co-corresponding author of a new study published in Science Translational Medicine that presents an innovative dural repair solution. He started the study as a neurosurgery resident at the Brigham and Women’s Hospital in Boston and Surgical Innovation Fellow at Boston Children’s Hospital.

“Our options are limited, consisting of suture repair or grafting, which can be difficult to perform. The surgical sealants currently available don’t adhere well to wet tissue, are too brittle, and lack the required toughness to reliably prevent cerebrospinal fluid leakage,” Wu said.

This new solution was developed by a collaborative team of bioengineers at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), and neurosurgeons at the Brigham and Women’s Hospital and Ohio State. Wyss Institute Founding Core Image Faculty member and SEAS Robert P. Pinkas Family Professor of Bioengineering David Mooney, PhD, led the research team.

This new solution was developed by a collaborative team of bioengineers at the Wyss Institute for Biologically Inspired Engineering at Harvard University and the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), and neurosurgeons at the Brigham and Women’s Hospital and Ohio State. Wyss Institute Founding Core Image Faculty member and SEAS Robert P. Pinkas Family Professor of Bioengineering David Mooney, PhD, led the research team.“We are excited to have opened a new perspective for neurosurgeons with this study that, in the future, could facilitate a variety of surgical interventions and lower the risk for patients who need them,” Mooney said.

Taking inspiration from nature

DTAs are an interesting example of “bioinspired engineering.” Almost a decade ago, Mooney’s group was looking for examples in nature that could help find new ways to seal and regenerate injured tissues in the body.

“Material approaches to tissue regeneration at the time mainly focused on creating strong ‘adhesion’ to various body surfaces, but not so much on strong internal ‘cohesion,’ or toughness in the face of tissue mechanical forces,” said co-first author Benjamin Freedman, PhD, a former Wyss Research Associate. “In addition, they didn’t stick well to wet tissue surfaces covered by different body

fluids.”

Their search led the group to the Dusky Arion slug (Arion subfuscus), which secretes a special kind of mucus to quickly glue itself in place to prevent predators from prying it off various surfaces.

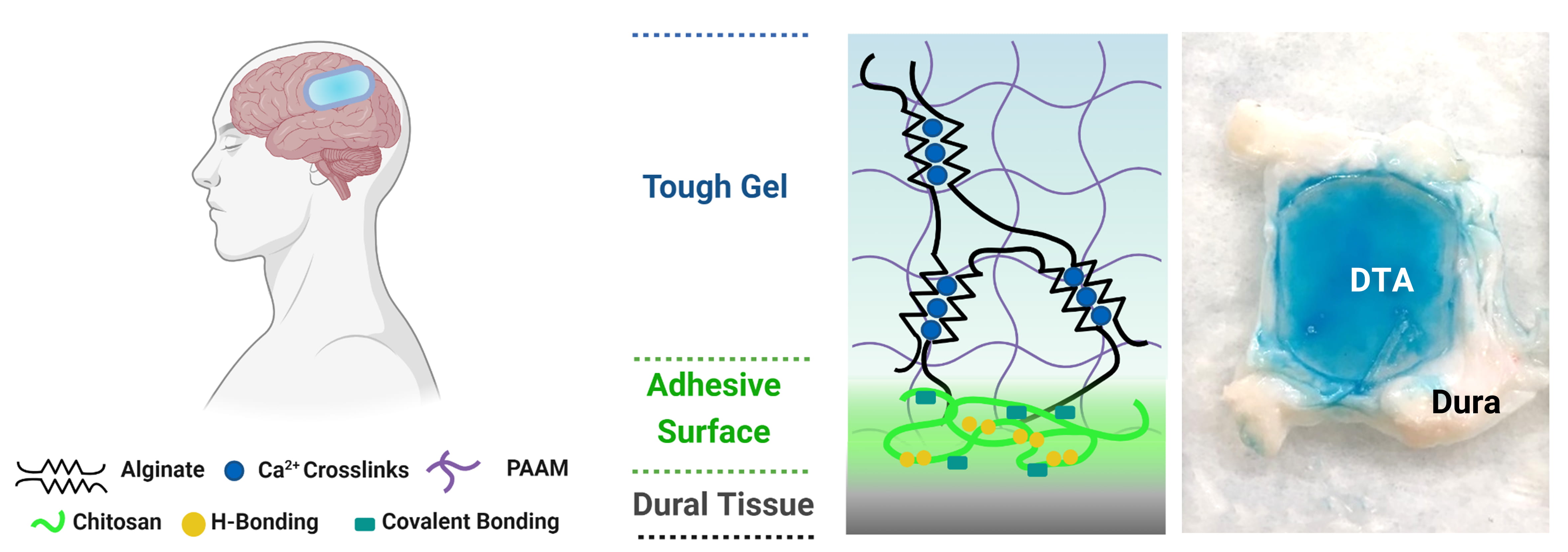

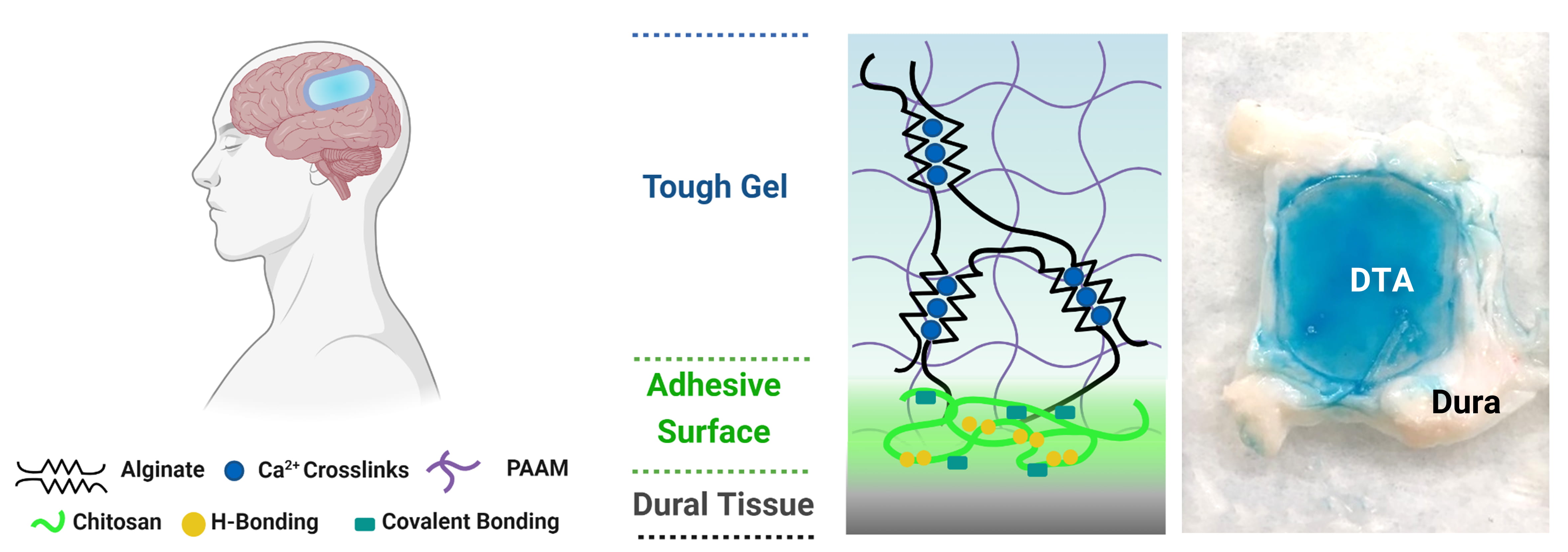

In part by mimicking properties of the slug’s mucus, the team developed a hydrogel consisting of two intermixed polymer networks:

- a network of permanently cross-linked acrylamide molecules that creates a highly elastic gel

- a network of reversibly cross-linked alginate molecules that can redistribute the energy produced by mechanical forces in underlying tissues

Paired with a highly adhesive layer that uses chitosan (a fibrous, sugar-based substance derived from shellfish), the composite Tough Adhesive (TA) hydrogel can bond to a variety of liquid-covered surfaces. It forms multiple types of chemical interactions with them to create a tight seal. These properties make it an ideal material  for dural repair. DTA’s composition follows the same TA basic formulation.

for dural repair. DTA’s composition follows the same TA basic formulation.

for dural repair. DTA’s composition follows the same TA basic formulation.

for dural repair. DTA’s composition follows the same TA basic formulation.The researchers found DTA performed better than currently used surgical sealants in tests using animal models and human-derived tissues in the lab. The team showed that DTA adheres significantly stronger and can withstand higher pressures before failing, compared to a currently used sealant.

DTA also maintained its structure and was fully biocompatible for at least four weeks, causing only minimal irritation. DTAs delivered the same benefits when tested using human cadaveric tissue.

“This multidisciplinary collaboration between bioengineers and neurosurgeons is a wonderful example of how Wyss technologies are invented and driven forward to improve patients’ lives,” said Wyss Institute Founding Director Donald Ingber, MD, PhD, who is also the Judah Folkman Professor of Vascular Biology at HMS and Boston Children’s Hospital, and the Hansjörg Wyss Professor of Bioinspired Engineering at SEAS.

The Wyss Institute at Harvard University and National Institutes of Health supported this work.

CAPTIONS

Image 1: Kyle Wu, MD, a neurosurgeon and assistant professor at The Ohio State University Wexner Medical Center, College of Medicine and James Cancer Hospital. Wu is co-first and co-corresponding author of this study published in Science Translational Medicine. Credit: The Ohio State University Wexner Medical Center

Image 2: A research collaboration of bioengineers and neurosurgeons has developed a new solution to re-sealing the dura that, using a multi-functional biomaterial, addresses key limitations of current repair methods. Credit: Peter Allen, Ryan Allen, and James C. Weaver. SEAS/MIT/Wyss

Image 3: The Dural Tough Adhesive (DTA) consists of two intermixed polymer networks: a polyacrylamide network that is permanently crosslinked and provides high elasticity, and an alginate that is reversibly crosslinked and can redistribute the energy produced by mechanical forces in underlying tissues. Adding a highly adhesive layer to this Tough Gel that uses chitosan, a fibrous, sugar-based substance derived from the outer skeletons of shellfish, enables DTA to form multiple chemical interactions with tissues like the dura that create a tight seal. Credit: Wyss Institute at Harvard University

PRESS CONTACTS

The Ohio State University Wexner Medical Center, Eileen Scahill, Eileen.Scahill@osumc.edu, 614-293-2092

Wyss Institute for Biologically Inspired Engineering at Harvard University; Benjamin

Boettner, benjamin.boettner@wyss.harvard.edu, 617-432-8232